Name

Ankit Chaudhary

director@recyvoltbattery.com

phone

+91-9899417898

Address

Plot No. 17 & 18, Anand Industrial Estate, Mohan Nagar, Ghaziabad, Uttar Pradesh 201007

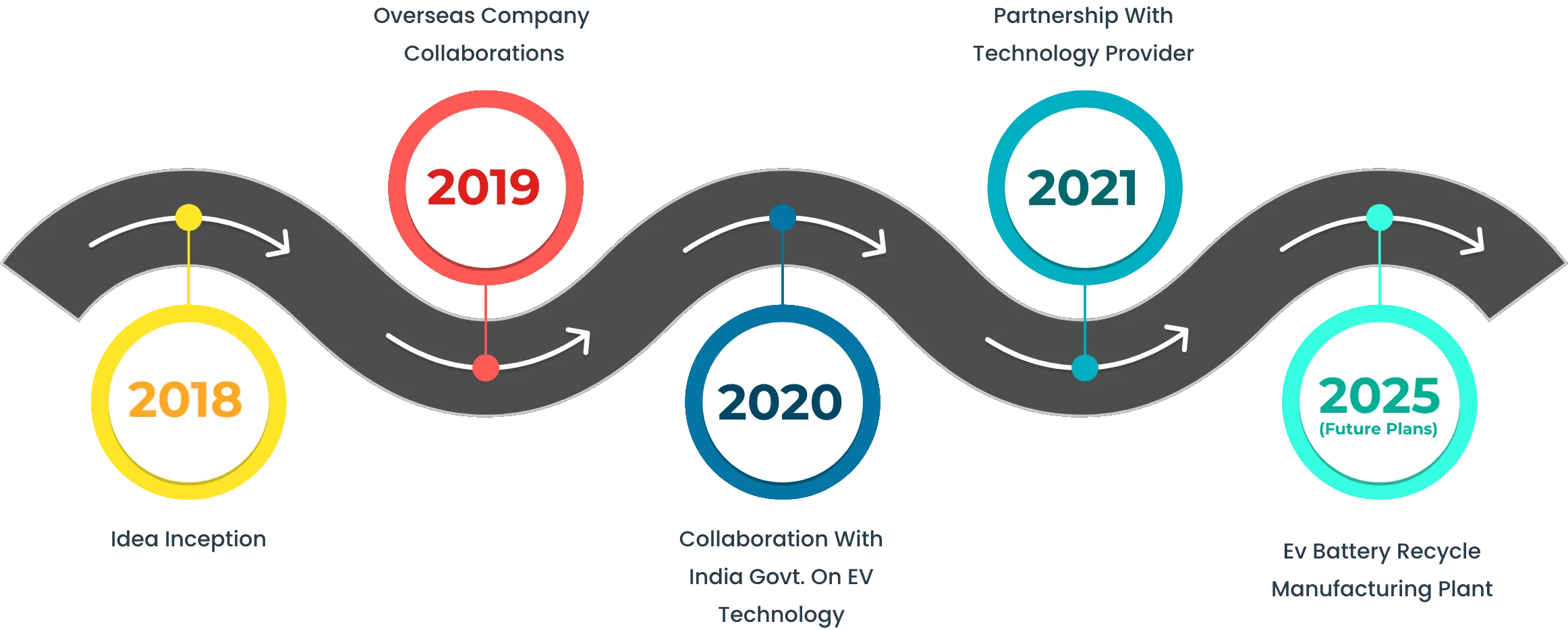

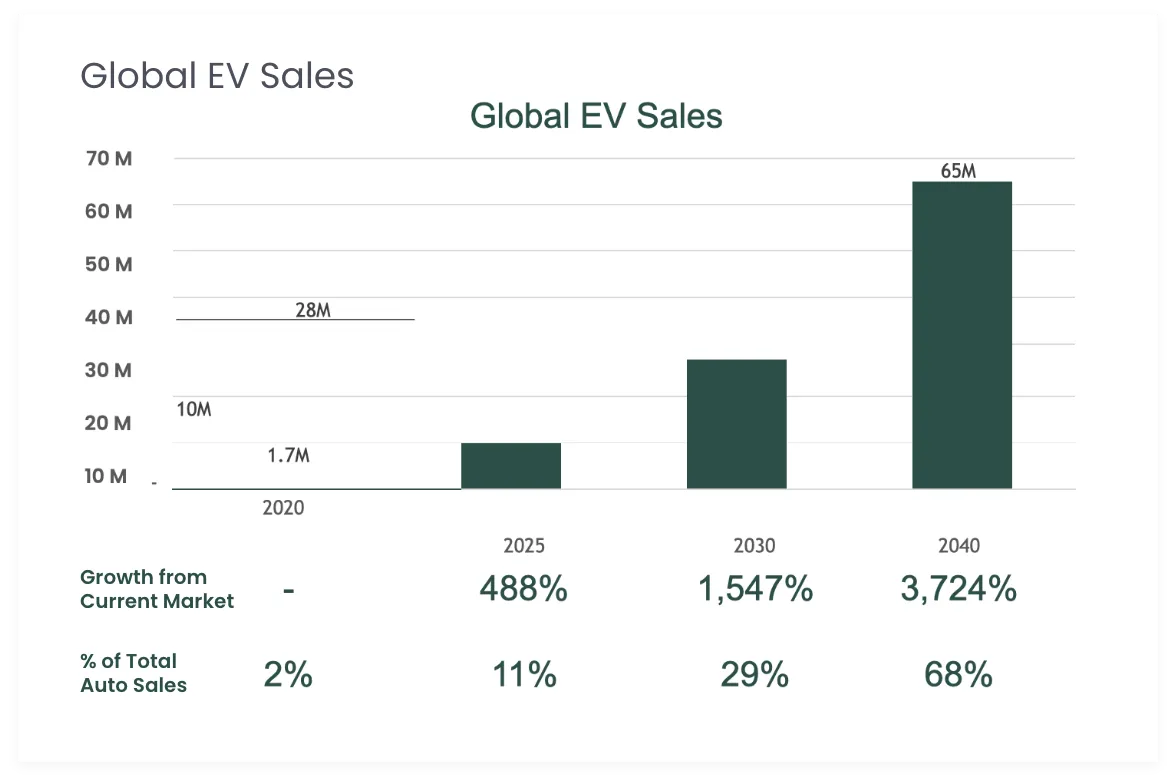

RECYVOLT Battery Recycle India is a leader in providing E2E consulting for the critical material and lithium-ion battery recycling. The Company is focused on developing collaborations for the circular economy required for the energy transition by treating spent batteries as a valuable resource, instead of hazardous waste – providing India with its first premier domestic source of Lithium, Nickel, Cobalt and Manganese.

Processing spent lithium-ion batteries to recover and reuse battery metals

Removing battery metals from primary resources with new scalable technologies

Gathering mineral resources directly from miners around the world

EV Recycling company to save environment

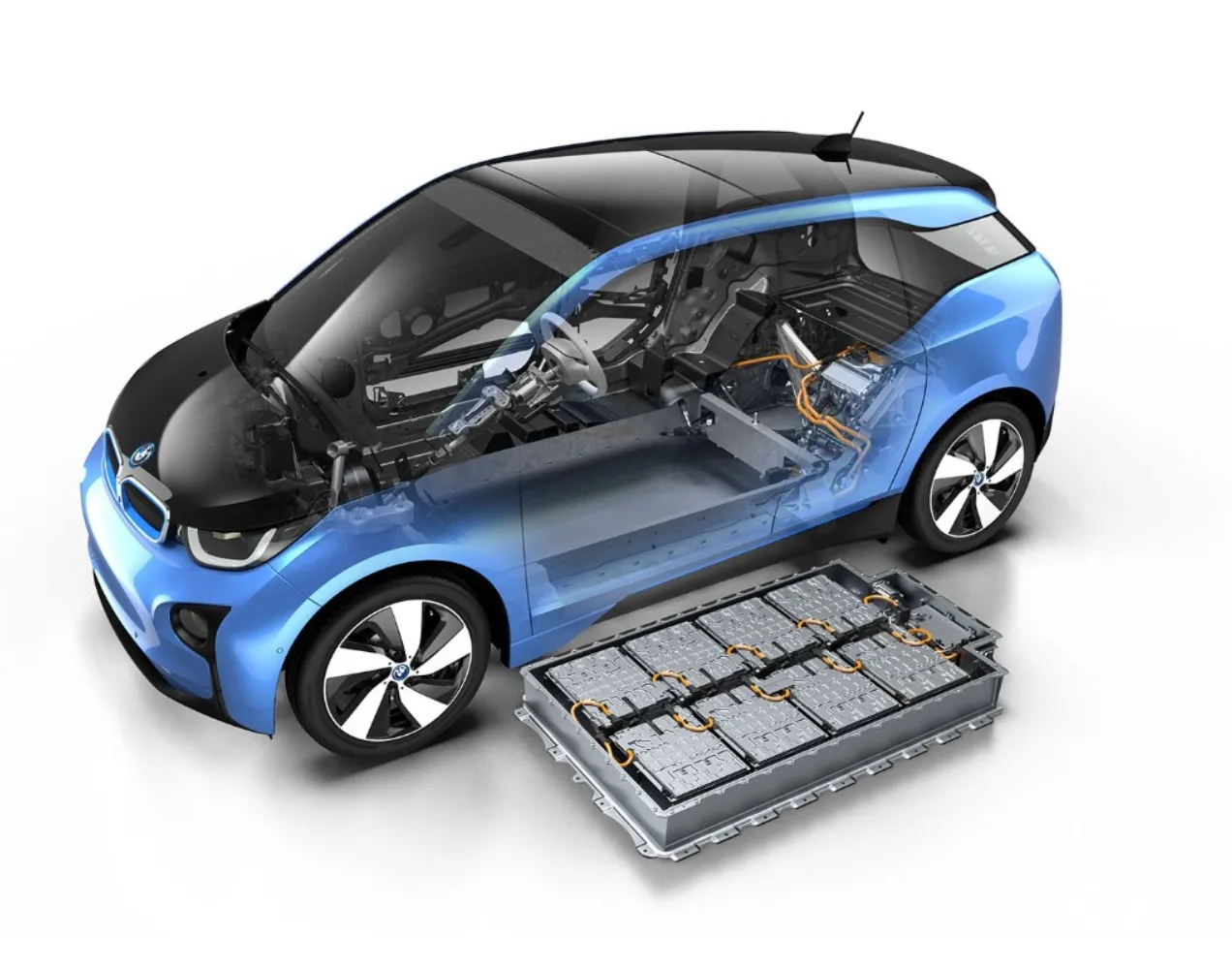

As the world moves away from petrol and diesel engines, the demand for electric vehicles is increasing. This is a positive move, as Electric Vehicles (EV) are a much more environmentally friendly solution for the automotive industry, and help to reduce the global reliance on fossil fuels. The increase in EV production does however inevitably mean an increase in the consumption of lithium-ion batteries. In fact, the global battery market has actually doubled in size over the last five years alone, and it is only going to get bigger.

Electrification of vehicles is a trillion dollar global opportunity and India has the potential to become a leader. As the automotive world is pacing to transform to the electric lane, India is also catching up the race. The concept of clean mobility with renewable power sources is now accepted by market leaders but there are several challenges from infrastructure to the basic question of what happens to EV batteries once their life cycles are over. Recycling EV batteries and extracting the unused metal is looking as an efficient solution to make EVs more affordable. Amidst Covid, Indians got a first-hand experienced of a truly clean air. The populous realized in one month that pollution is solvable, clean air is possible and that electrification is a critical step to transition. We were already seeing a huge interest in EVs pre-Covid and now the momentum is only increasing.

As Indian economy is caught up in a slowdown, the future of the automobile industry is pinned on electric vehicles. And EV technology in India is, in turn, highly dependent on innovation and government incentives. At the same time, the government has to tackle the slowdown and invest in future-ready technology at the same time. This has led to a deep dichotomy in the Indian electric vehicles market which has put the future of EV technology in India in a bit of a muddle.

Growing EV adoption and infrastructure growth is leading to a large push towards electrification

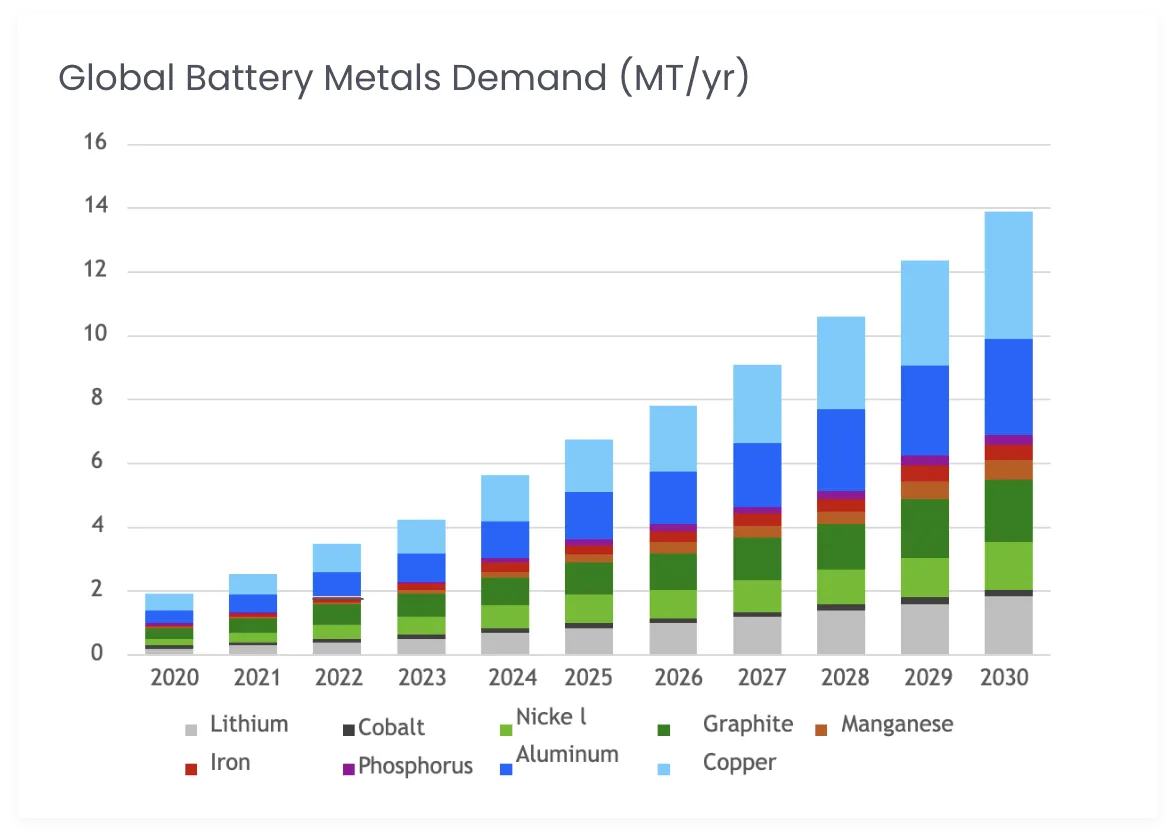

There is not enough primary supply to meet the demand for battery materials.

Battery recycling is the green, sustainable solution for the battery materials supply shortage

Demand for Battery Metals, especially copper and aluminum is set to grow almost 600% through 2030, Thermal refiners and traditional hydrometallurgical processes are primarily focused on Nickel and Cobalt, missing large value from other metals The battery recycling process of tomorrow must be able to recover a wide range of metals in order to meet global demand